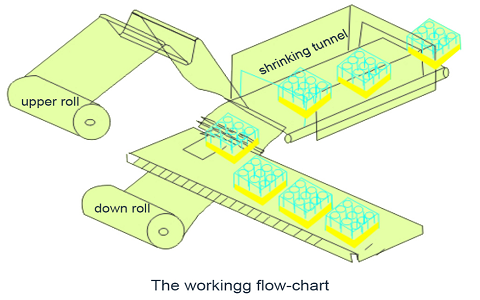

Detailed Description Of S10 shrink wrapping machine:

shrink Wrapper

designed L type structure can effectively save workshop space.also with below features:

1.frequency converter speed adjust,two segment convey device.

2.Bottle pushing, thermo sealing and cutting whole movement adopt to pneumatic fracture.

3.Proximity switch control film length.

4.Touch screen, PLC system greatly increase facility movement reliability.

5.double-wind recycle fan machine, ensure shrinkage tunnel inside even temperature.

6.super big wind-volume cooling system, ensure quickly get into shape .

7.anti-high temperature teflon convey belt, convey steadily, high-strength anti-abrasion.

8.frequency limitless speed adjust convey belt frame.

9.convey belt height can make according client requirement, adjust range:±50mm

10.bottle convey machine can meet with client bottle forward direction requirement, can lengthen or shorten.

11.wing stainless steel heating system, endurance.

12.meet with product instant stop requirement product-bearing rack device ensure production line consistency.

Basic Configuration:

Shrink packaging machine

1.Thinget:5.7 inch touch screen, PLC controlling system

2.Taiwan AIRTAC pneumatic component 1set

3. Taiwan Telta frequency converter 3 set

4. stainless steel wing heating tube 12 piece

also can customized basic configuration according to end users’ requirements.

Technical Parameter:

shrink package machine

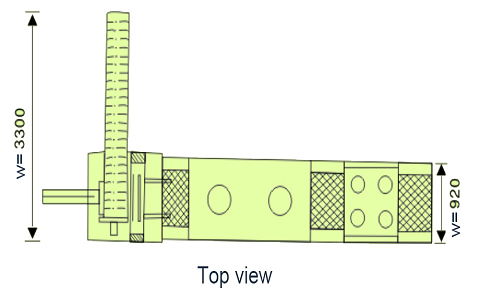

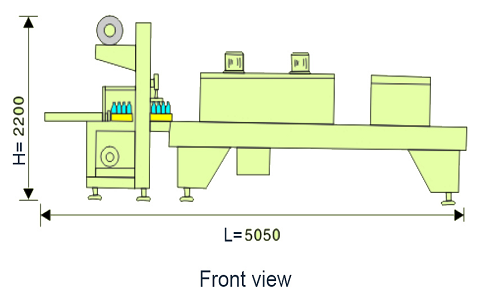

1.facility external size:L5050*W3300*H2100mm

2.wrappage max size:L600*W400*H350mm

3.shrinkage film material:PE、PVC、POF

4.shrinkage thermo thickness:0.03-0.15mm

5.thermo shrinkage tunnel temperature: 160 – 260°can adjust at will.

6.max output per minute:8-12bag

7.facility power:18Kw

8.actual power:15Kw/hr

9.pressure requirement:380/220V

10.facility weight:1.2T

11.fan machine:1.1Kw 2set 380V, 65W 4set 380V

Application Condition and Requirement:

Application of shrink wrap equipment

1.package type:

1.1 suitable bottle volume: 350/500/550/600ML

1.2 big bottle:4*6 or 4*5 . small bottle:3*4, 3*5

1.3 four type of package: 1.2 1L/1.5L/2L/2.5L

1.4 big bottle:3*3 or 3*4. small bottle:2*2 or 2*3

2. Regarding can, we suggest adopt to package with tray, pack steadily.

3. package speed:8-15bottles/min

4. meet with pre-treatment filling speed of filling machine. 4.1 350/500/550/600ML

4.1 big bottle:4*6 or 4*5, (12000-15000b/hr)

4.2 small bottle:3*5,3*4, (8000-10000b/hr). 4.2 1L/1.5L/2L

4.3 big bottle:3*4,3*3(5000-6000b/hour)

4.4 small bag:2*3,2*2(3000-4000b/hr).

5. package material:PE thermo shrinkage film width:(200-600mm)