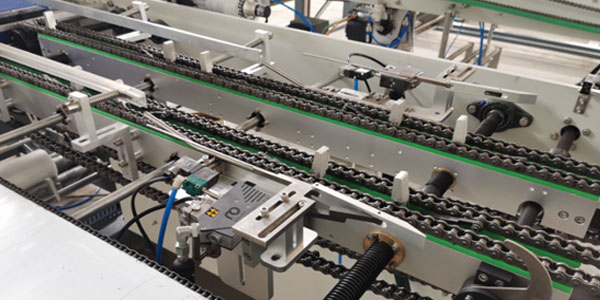

Detailed Description of Tray Packer:

horizontal load case and tray packer

Pads and trays Stretch film shrink wrapping machine by KOMAL AH-Series.

- Frequency converter speed adjust.

- Bottle pushing,thermo sealing and cutting whole movement adopt to pneumatic fracture.

- Proximity switch control film length.

- Touch screen,PLC system greatly increase facility movement reliability.

- Three-wind recycle fan machine,ensure shrinkage tunnel inside even temperature.

- Super big wind-volume cooling system,ensure quickly get into shape .

- Anti-high temperature teflon convey belt,convey steadily,high-strength anti-abrasion.

- Frequency limitless speed adjust convey belt frame.

- Convey belt height can make according client requirement,adjust range:±100mm.

- Wing stainless steel heating system,endurance.

- Meet with product instant stop requirement product-bearing rack device ensure production line consistency.

Basic Configuration:

| No | Name | Number | Brand | |

| 1 | board production component | |||

| 2 | Plant metal component | |||

| 3 | pneumatic component | 1 | Taiwan Airtec | |

| 4. | Electric controlling component and accessory | |||

| Glue machine | 1 | RO | ||

| Photoelectric switch | 1 | South Korea Autonics | ||

| Proximity switch | 4 | South Korea Autonics | ||

| PLC | 1 | Siemens | ||

| Touch screen | 1 | Siemens | ||

| Frequency converter | 2 | Taiwan TECO | ||

| AC contactor | 9 | France Schneider | ||

| Mid-relay | 12 | OMRON | ||

Technical Parameter:

1. machine size:L14000*W1250*H2100mm

2. outside size:machine main part:6800*1250*2350mm

3. Shrink tunnel:4200*1100*1700mm

4. conveyor : 3000*1200*950mm

5. max wrapping size:L420*W280*H350mm

6. shrinking film material:PE

7. thickness of shrinking film:0.03-0.15mm

8. thermo shrinkage tunnel max temperature:160 – 260°can adjust

9. max output per minute::18 packages/min

10. machine power:40Kw

11. actual power:30Kw/hr

12. voltage requirement:380V/50-60HZ

13. weight:3000KG

14. air pressure:0.6-0.8mpa

15. working noise:≤65db

16. feed bottle conveyor belt width:541mm

17. fan:1.1Kw 3sets 380V, 60W 6sets 380V

Application Condition and Requirement:

1.package type:

(1)350/500/550/600ML big bag:4*6,4*5 ;small bag,3*4,3*5 four type of package.

(2)1L/1.5L/2L/2.5L big bag:3*3,3*4;small bag,2*2,2*3 four type f package

2. Regarding can, we suggest adopt to package with tray ,pack steadily.

3.package speed:18 bag/min

4.meet with pre-treatment filling speed of filling machine.

(1) 350/500/550/600ML big bag:4*6,4*5,(24000-29000b/h),small bag:3*5,3*4,(15000-18000b/h).

(2)1L/1.5L/2L big bag:3*4,3*3(10000-14000b/h), small bag:2*3,2*2(5000-7000b/h).

5.package material:PE thermo shrinkage film width(200-600mm),thickness(0.03-0.12mm)