Detailed Description:

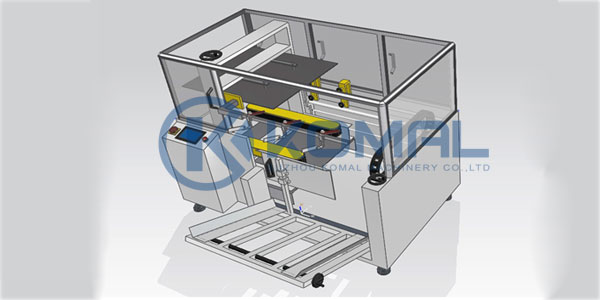

GT10 Carton Box Packing Machine

Compared with the traditional packing machine, this machine has the following advantages:

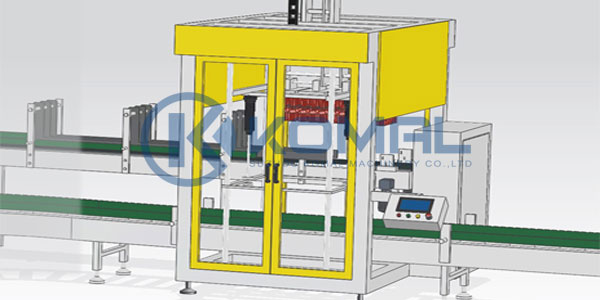

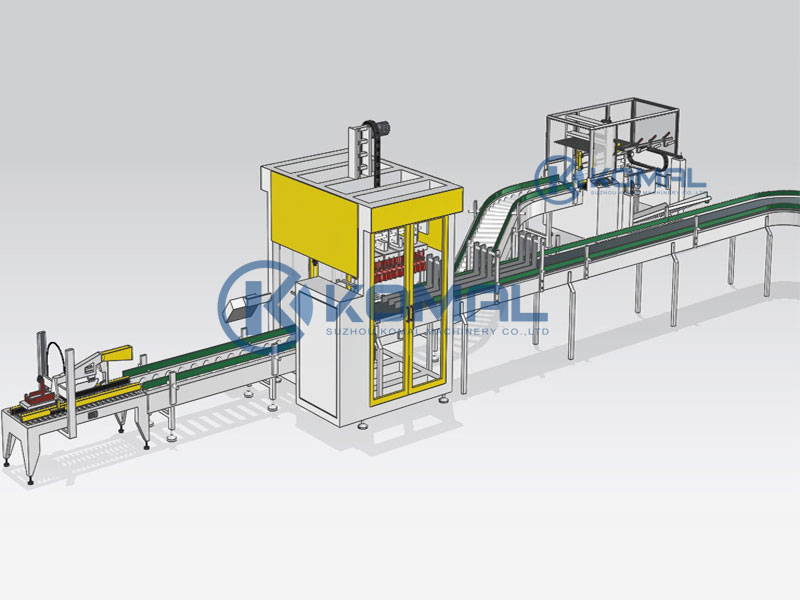

1. Adopt side feed bottle way: small footprint, simplify the conveying system before the packing machine, reduce the investment cost of the whole line equipment.

2. Adopt three levels of decompression: product fully decompression, make catch bottle head and product alignment accurate, grab bottle success rate of 100%,

product into the packing process, in the no pressure, smooth delivery state, basically stop pouring bottle phenomenon.

3. Main transmission adopts frequency control and PLC control technology, combined with the man-machine interface, realize stepless speed regulation, the main control by German SIEMENS PLC, with fast communication ability and powerful diagnostic function, to ensure the reliability of the system. The operation is convenient, the structure is compact and reasonable, and the degree of automation is high.

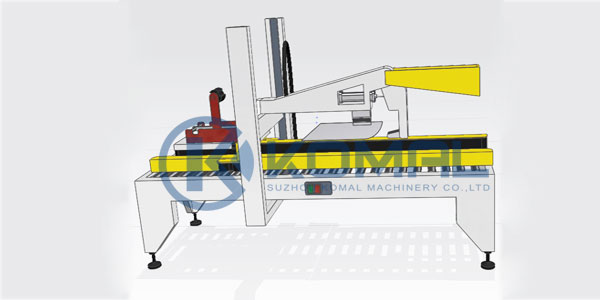

4. Reliable work: This machine is a special pneumatic components to achieve grasping and placing products. Through mechanical operation, pneumatic and electrical control, the product is accurately and reliably loaded into the carton from the bottle stand.

5. Stable operation: the whole packing process is driven independently by frequency conversion motor, and the different mechanical mechanisms enable the product to ascend, translation and landing, and combine with pneumatic, electrical and optical control to realize automatic operation. Movement coordination, smooth and accurate movement.

Technical Parameter:

| Model | GT10 |

| capacity: | one time pack 4cartons(3*4)–20cartons/min,one time pack two cartons(4*6)–10cartons/min |

| Overall Size | 2500*2000*2500(mm) |

| Packing form | carton packer |

| Bottle type | 200ml-1500ml |

| packing number of layer | one layer |

| Machine power | 5.0kw |

| Comprressor air | 1500L/min 0.6-0.8Mpa |

| applicable product | Mineral water, beverage, lubricant, soy sauce, shampoo, detergent, shower gel, aerosol, etc |

| Driven Type | Electric |

| voltage | 380V/220V |

| Weight | 3000Kg |

Basic Configuration:

GT10 Carton Box Packing Machine

- Germany IGUS: Linear guide rail

- Germany SICK :Photoelectric control system

- Germany Siemens:PLC & controlling system (touch screen controlling)

- Servo & motor:Taiwan Delta—2sets

- AIRTAC: Pneumatic components(cylinder,Solenoid valve)

- Taiwan TECO: Frequency converter

- Low voltage electrical apparatus:Schneider

- Photoelectric component:AUTONICS

Application Condition and Requirement:

- Goods easy broken or deformation during delivery.

- Products must enter the machine with relatively steady speed,feeding speed upstream products should be able to control,prevent excessive squeeze between products.

- At the exit of the carton ,packaging products must be carefully removed in a timely manner,to ensure the normal packaging process.