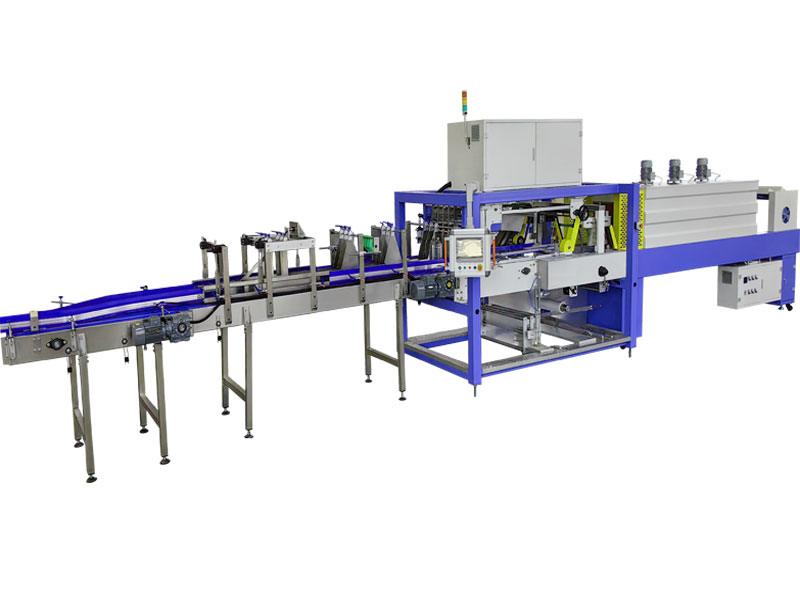

Detailed Description

1.Appearance concision,beauty,fracture novel,unique,convenient to maintain.

2.Big screen, manipulation interface LCD Chinese and English display.

3.Pneumatic expand support membrane roller, membrane change is quick, membrane change just need two minute.

4.Membrane tension transport, even and plat, film cutting controlling is precision, cut is tidy.

5.Super servo controlling technology can keep each fracture precision in-phase, transmission is reliably.

6.Heating case fracture is reasonable,heat insulation and warm keeping,temperature controlling precision is highly.

7.Mechanism drive part adopt to heating treatment stainless steel or medium carbon steel ect material.

surface spray coating quality is fine; whole machine anti-rust character is very highly.

8.While all the electricity,pneumatic controlling accord with latest international applied criterion.

9.While electricity cut, set manpower rotary conveyor belt device, easy to move heating tunnel inside product outside.

Basic Configuration

| No | Name | Number | Brand | Place of origin |

| 1 | Touch screen | 1set | Inovance | CHINA |

| 2 | Servo electrical motor | 3sets | Inovance | CHINA |

| 3 | Servo controller | 3sets | Inovance | CHINA |

| 4 | Frequency converter | 2sets | TECO | Taiwan |

| 5 | Inspection switch | 5sets | Autonics | Korea |

| 6 | pneumatic components | Airtac | Taiwan | |

| 7 | Electrical components | Schneider | France | |

| 8 | Reduce speed motor | 2sets | Guangzhou | Guangzhou |

| 9 | Inflatable shaft | 1pcs | Xihang | Made-in-China |

| 10 | High quality stainless steel material for heating network 9.24M×663mm | 1pcs |

Technical Parameter

1.Facility model: D20

2.Facility overall size: L10700*1560*2450H mm

3.Max package size:L420 *W280 *H350 mm

4.Shrinkage film material: PE film

5.Shrink membrane thickness: 80~90um

6.per min capacity :18-25 packages/min

7.Power supply max load relied: Total load of power supply: 45kW for heating

tunnel, 10kW for mechanical part

8.Machine usage compressor air pressure:0.6~0.8Mpa;max gas consumption

quantity is: 0. 25NM3/min

9.Conveyor belt max width: 600mm,height is: 1500~1100(mm)(can adjust)

10.Pressure requirement: 380/220V

11.Facility weight: 3500kg

Application Condition and Requirement:

1.Packaging Specification:

3row*3arrange/bag,4row*6arrange/bag,3row*4arrange/bag,

4row*5arrange/bagor accord with client requirement

2.Applicable container shape:

Round glass bottles, PET bottles, cans, with an outer diameter of 60-90 mm and a height of 120-150mm,

(Note: replace relevant parts, which is more applicable)

According to the specific requirements of your company: the corresponding software of the packaging form

of the relevant bottle type has been pre installed. When changing the bottle type, you only need to switch on the control panel, which is very convenient to operate.

3.Package speed :

18-25 packages/min(Continuous stepless speed regulation)

4.Requirements for packaging materials:

Material: PE; Density: 0.91~0.92 g/cm3

Thickness: 80~90um

Maximum roll diameter: 500mm

Diameter of film reel core: Φ 76~ Φ 80mm

Tensile strength: longitudinal and transverse meet gb13022 standard